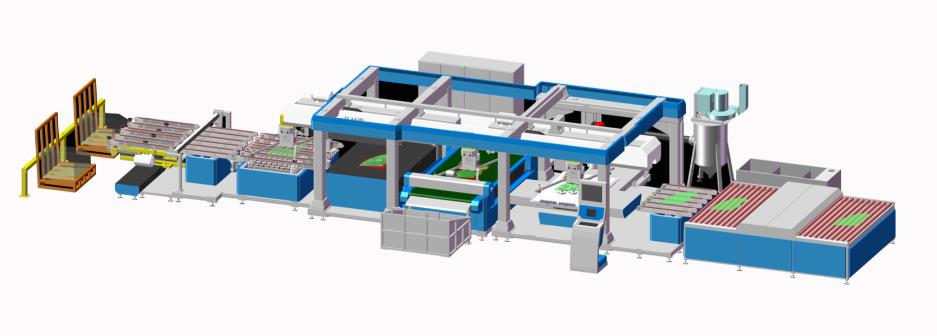

Product introduction:

The complete

production line includes: 1 set single-sided double-station automatic loading table; 1 set automatic positioning machine; 1 set cutting machine; 1 set breaking machine; 1 set glass edging machine; and 1 set of handling robots, and other ancillary devices, it can implement Automotive Glass's cutting, grinding and washing function.

this production line also can connect with water jet and drilling machine or CNC, then will add more function, ensure implement complete processing for automotive glass.

1. Processing

range:

WL2000*1250 as sample

* Maximum

processing glass size: 2000mm long (Y direction), wide (X direction) 1250mm

* Minimum processing

glass size: length 350mm (Y direction), width (X direction) 100mm

* Glass thickness:

2-6mm

* Maximum size of

glass to be perforated: length 2000mm (Y direction), width (X direction) 1400mm

2. Equipment accuracy and

speed:

1) Cutting machine

accuracy: plus or minus 0.1mm (any 1 meter).

2) Precision of the

edger: plus or minus 0.1mm (any 1 meter).

3) Cutting machine

speed: 1 to 60 m / min (automatic shifting according to arc size, inner arc,

outer arc, cutting machine speed).

4) Edger speed: 1 to

40 m / min (automatic shift according to arc size, inner arc, outer arc, and

edging speed).

5) Robot speed: 60 to

130 m / min

Remark: We can design and make more specification according to customer's requirement.

豫公网安备 号

豫公网安备 号